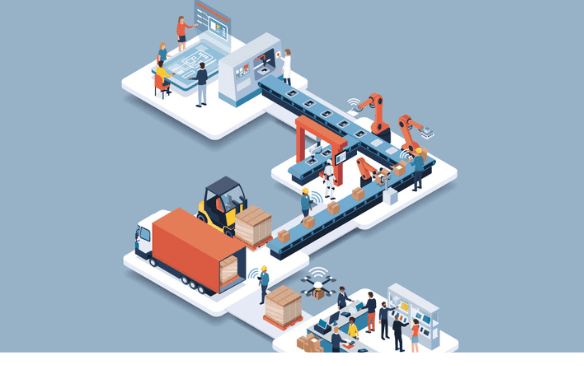

Vendor consolidation has been popular for several decades. It is a supply chain management strategy, where company reduces the Vendors by designing the goal for procurement process, cost reduction, improving the standards of business procedure.

Importance of Vendor Consolidation

Increased business growth leads to increased demand as well. This results in interacting with more vendors. This results in more vendor acquisitions, which can lead to a wider number of suppliers. Whereas each supplier needs to be interacted individually, vendor consolidation resolves this issue by reducing the number of suppliers to a minimum reliable vendor.

Benefits of vendor consolidation

Process to implement vendor consolidation

Talk to one of Supply Chain Specialists to find out, how to optimize your supply chain and implement vendor consolidation.